- +971 543 497 827

- enquiries@rigrock.ae

Jump To:

CNC Machines (Computer Numerical Control) in Oil and Gas:

CNC machines play a crucial role in the oil and gas industry for precision machining of various components used in drilling equipment, pumps, valves, and other machinery. These machines are used to manufacture parts like gears, shafts, housings, and connectors with high accuracy and consistency. CNC machining ensures that critical components meet the tight tolerances required for reliable performance in harsh oil and gas environments. Additionally, CNC technology allows for the production of custom parts tailored to specific requirements, contributing to equipment efficiency and reliability.

CNC Machines Manufacturers:

- Haas Automation:

Haas is a prominent manufacturer of CNC machine tools, known for its wide range of products including vertical and horizontal machining centers,

CNC lathes, rotary tables, and more. They are recognized for their reliability, precision, and user-friendly interface, catering to various industries

worldwide. - Mazak Corporation:

Mazak is renowned for its innovative CNC machining solutions, including multitasking machines, 5-axis machining centers, and turnkey

manufacturing systems. They are recognized for their high-performance machines, advanced control systems, and extensive support network.

Haas Automation (CNC Machines):

- Haas VF Series Vertical Machining Centers: Known for their versatility and reliability, the VF series offers a range of vertical machining centers

suitable for a variety of applications, from high-speed machining to heavy-duty cutting. - Haas ST Series CNC Lathes: The ST series of CNC lathes are renowned for their precision, productivity, and ease of use, making them ideal for

turning operations in various industries. - Haas EC Series Horizontal Machining Centers: The EC series of horizontal machining centers deliver high-performance machining capabilities

with features like high-speed spindles, large work envelopes, and advanced control systems.

Injection Molding Machines in Oil and Gas:

Injection molding machines are utilized in the oil and gas industry for producing a wide range of components, particularly those made from plastic materials. These components include seals, gaskets, connectors, and housing parts for various equipment used in exploration, production, refining, and transportation processes. Injection molding enables the production of parts with intricate geometries and high strength, capable of withstanding challenging operational conditions such as high pressures, corrosive environments, and temperature extremes. By using injection molding, manufacturers can achieve cost-effective mass production of components essential for the oil and gas sector.

Injection Molding Machines Manufacturers:

- Engel: Engel is a leading manufacturer of injection molding machines, offering a diverse range of hydraulic, electric, and hybrid machines for various

applications. They are known for their precision, energy efficiency, and advanced technologies such as tie-bar-less designs and integrated

automation solutions. - KraussMaffei Group: KraussMaffei is a global provider of injection molding technology, offering high-performance machines for thermoplastics and thermosetting plastics

processing. They are recognized for their expertise in large-scale injection molding, innovative process technologies, and digital solutions. - Arburg: Arburg is renowned for its precision injection molding machines and additive manufacturing systems. They offer a wide range of machines for

standard and specialized applications, along with automation and turnkey solutions. Arburg is known for its quality, reliability, and customer-centric

approach.

Engel (Injection Molding Machines):

Engel Victory Series: The Victory series of injection molding machines offers a wide range of models with innovative features such as tie-bar-

less designs, energy-efficient drive systems, and modular configurations for maximum flexibility.Engel Duo Series: The Duo series combines two-platen technology with servo-hydraulic drive systems to provide high precision, energy

efficiency, and versatility for molding large and complex parts.Engel e-motion Series: The e-motion series features all-electric injection molding machines known for their precision, speed, and energy

efficiency, making them suitable for cleanroom environments and high-tech applications.

3D Printers in Oil and Gas:

3D printing technology is increasingly adopted in the oil and gas industry for rapid prototyping, customized tooling, and manufacturing of complex components. In exploration and production, 3D printing is used to create prototypes of drilling tools, sensors, and equipment components, allowing for iterative design improvements and faster product development cycles. Additionally, 3D printing enables the fabrication of spare parts on demand, reducing downtime and inventory costs for oil and gas operators. Metal 3D printing is particularly valuable for producing corrosion-resistant components, heat exchangers, and customized parts for downhole tools and well-completion systems. Overall, 3D printing offers the oil and gas industry greater flexibility, efficiency, and innovation in product design and manufacturing.

3D Printers Manufacturers:

- Stratasys: Stratasys is a leading manufacturer of 3D printing systems, offering a diverse range of industrial-grade printers for additive manufacturing applications. They are known for their FDM (Fused Deposition Modeling) and PolyJet technologies, catering to industries such as aerospace, automotive, healthcare, and consumer goods.

- 3D Systems: 3D Systems is a pioneer in the field of 3D printing, providing a comprehensive portfolio of printers, materials, and software solutions for prototyping, production, and customization. They are recognized for their SLA (Stereolithography), SLS (Selective Laser Sintering), and DMP (Direct Metal Printing) technologies.

- EOS GmbH: EOS is a leading manufacturer of industrial 3D printing systems, specializing in metal additive manufacturing technology. They offer a range of metal powder bed fusion systems known for their high precision, quality, and reliability, serving industries such as aerospace, healthcare, and automotive.

Stratasys (3D Printers):

- Stratasys Fortus 450mc: The Fortus 450mc is a high-performance FDM 3D printer designed for producing functional prototypes, end-use parts, and tooling with engineering-grade thermoplastics.

- Stratasys J750 Digital Anatomy Printer: The J750 Digital Anatomy Printer is a multi-material 3D printer optimized for medical applications, allowing the creation of realistic anatomical models for surgical planning, training, and education.

- Stratasys Origin One: Origin One is a production-grade polymer 3D printer utilizing SLA technology, offering high throughput, exceptional surface finish, and material versatility for manufacturing custom parts and prototypes.

POWER AND ENERGY EQUIPMENT

Jump To:

Generators:

Generators are devices that convert mechanical energy into electrical energy. In the context of the oil and gas industry, generators are often used to provide backup power to critical equipment and facilities in case of power outages. They can also be employed in remote locations where grid power is not available, such as offshore platforms or remote drilling sites. Generators come in various sizes and types, including diesel, natural gas, and dual-fuel generators, and they play a crucial role in ensuring uninterrupted operations in the oil and gas sector.

Generators: a. Caterpillar Inc:

- Model: Cat® Diesel Generators

- Model: Cat® Natural Gas Generators

- Model: Cat® Bi-Fuel Generators b. Cummins Inc.

- Model: Cummins® Diesel Generators

- Model: Cummins® Natural Gas Generators

- Model: Cummins® Biogas Generators c. Generac Power Systems:

- Model: Generac® Diesel Generators

- Model: Generac® Natural Gas Generators

- Model: Generac® Bi-Fuel Generators

Turbines (Steam Turbines, Gas Turbines):

Turbines are rotary mechanical devices that extract energy from a fluid flow and convert it into useful work, typically rotational mechanical energy. In the oil and gas industry, both steam turbines and gas turbines are commonly used for power generation and as drivers for various types of equipment. Steam turbines utilize high-pressure steam generated by boilers to drive a turbine rotor, while gas turbines combust fuel (natural gas, diesel, etc.) in a combustion chamber to produce high-velocity gas that drives the turbine blades. These turbines are often employed in power plants, refineries, and offshore platforms to generate electricity and drive compressors, pumps, and other machinery essential for oil and gas operations.

Turbines: a. General Electric (GE) Power:

- Model: GE 9HA Gas Turbine

- Model: GE 7HA Gas Turbine

- Model: GE 7F.05 Gas Turbine b. Siemens Energy

- Model: Siemens SGT-800 Gas Turbine

- Model: Siemens SGT6-5000F Gas Turbine

- Model: Siemens SGT5-8000H Gas Turbine c. Mitsubishi Power (formerly Mitsubishi Hitachi Power Systems):

- Model: Mitsubishi M501JAC Gas Turbine

- Model: Mitsubishi M701JAC Gas Turbine

- Model: Mitsubishi G-Series Gas Turbine

Transformers:

Transformers are electrical devices used to transfer electrical energy between circuits through electromagnetic induction. They are crucial components in power distribution systems, stepping up or stepping down voltage levels as required to match the requirements of different equipment and facilities. In the oil and gas industry, transformers are used in various applications, including power distribution networks, substations, and electrical systems on drilling rigs, platforms, and refineries. They help ensure efficient and safe transmission of electricity, voltage regulation, and isolation of electrical circuits, contributing to the reliable and uninterrupted operation of oil and gas facilities.

Transformers:

- ABB Group:

- Model: ABB Power Transformer – ABB AbilityTM TXpertTM

- Model: ABB Distribution Transformer – ABB AbilityTM TXpertTM

- Model: ABB Resilient Transformer – ABB AbilityTM TXpertTM

- Siemens Energy:

- Model: Siemens Power Transformer – Siemens Sensformer®

- Model: Siemens Distribution Transformer – Siemens Sensgear®

- Model: Siemens Resilient Transformer – Siemens Sensformer®

- Schneider Electric:

- Model: Schneider Electric Power Transformer – Trihal Cast Resin Transformers

- Model: Schneider Electric Distribution Transformer – Trihal Cast Resin Transformers

- Model: Schneider Electric Resilient Transformer – Trihal Cast Resin Transformers

PUMPS AND COMPRESSORS

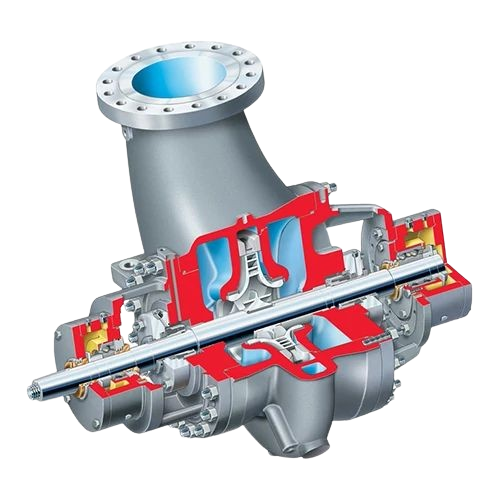

Centrifugal Pumps:

- Centrifugal pumps are commonly used to transport fluids in various industrial processes, including oil and gas operations.

- They work by converting rotational kinetic energy into hydrodynamic energy to move fluid through a system.

- In oil and gas applications, centrifugal pumps are used for tasks such as transferring crude oil, circulating drilling mud, and boosting water or hydrocarbon liquids through pipelines.

Reciprocating Pumps:

- Reciprocating pumps operate by using a piston or diaphragm to create a reciprocating (back-and-forth) motion, which generates pressure to move fluid.

- These pumps are often employed in oil and gas processes for tasks such as injecting chemicals into wells for enhanced oil recovery, as well as for metering and transferring fluids in various stages of production and refining.

Vacuum Pumps:

- Vacuum pumps are designed to remove gas molecules from a sealed volume to create a vacuum.

- In the oil and gas industry, vacuum pumps are utilized for applications such as degassing crude oil or gas streams, creating vacuum conditions in refining processes, and facilitating the operation of distillation units.

Air Compressors:

- Air compressors are devices that convert power (usually from an electric motor, diesel engine, or gas engine) into potential energy stored in compressed air.

- They are essential in oil and gas operations for tasks like providing compressed air for pneumatic control systems, powering pneumatic tools, and supplying air for instrument air systems used in monitoring and controlling processes.

Hydraulic Pumps:

- Hydraulic pumps are used to generate flow to move hydraulic fluid and transmit power within hydraulic systems.

- In the oil and gas sector, hydraulic pumps are employed in various applications, including powering hydraulic cylinders for wellhead control, actuating valves in pipelines and processing facilities, and driving hydraulic machinery used in drilling and production operations.

PUMPS AND COMPRESSORS

PRODUCTS AND MANUFACTURERS

Jump To:

Sulzer:

- Product: Sulzer ANSI and API Process Pumps

Brand: Sulzer Ahlstar and Sulzer API Series - Product: Sulzer Submersible Pumps

Brand: Sulzer ABS and Sulzer Flygt Series - Product: Sulzer Multistage Pumps

Brand: Sulzer HPT and Sulzer HPDM Series

Grundfos:

- Product: Grundfos CR Vertical Multistage Centrifugal Pumps

Brand: Grundfos CR Series - Product: Grundfos SP Submersible Borehole Pumps

Brand: Grundfos SP Series - Product: Grundfos NB End-Suction Centrifugal Pumps

Brand: Grundfos NB Series

KSB:

- Product: KSB Omega Centrifugal Pumps

Brand: KSB Omega Series - Product: KSB Movitec Multistage Pumps

Brand: KSB Movitec Series - Product: KSB Amarex Submersible Pumps

Brand: KSB Amarex Series

Cat Pumps:

- Product: Cat Pumps 66DX Series High-Pressure Plunger Pumps

Brand: Cat Pumps 66DX Series - Product: Cat Pumps 3CP Plunger Pumps

Brand: Cat Pumps 3CP Series - Product: Cat Pumps 5CP Plunger Pumps

Brand: Cat Pumps 5CP Series

Gardner Denver:

- Product: Gardner Denver GD 2500Q Hydraulic Fracturing Pumps

Brand: Gardner Denver GD 2500Q Series - Product: Gardner Denver TEE Triplex Pumps

Brand: Gardner Denver TEE Series - Product: Gardner Denver PZ Mud Pumps

Brand: Gardner Denver PZ Series

Flowserve:

- Product: Flowserve LNN Between-Bearing, Single-Stage Pump

Brand: Flowserve LNN Series - Product: Flowserve IDP Axially Split, Multistage Pump

Brand: Flowserve IDP Series - Product: Flowserve HTO Boiler Feed Water Pump

Brand: Flowserve HTO Series

Atlas Copco:

- Product: Atlas Copco ZR/ZT Rotary Screw Air Compressors

Brand: Atlas Copco ZR/ZT Series - Product: Atlas Copco GHS VSD+ Oil-Sealed Rotary Screw Vacuum

Pumps

Brand: Atlas Copco GHS VSD+ Series - Product: Atlas Copco NGP Nitrogen Generators

Brand: Atlas Copco NGP Series

Ingersoll Rand:

- Product: Ingersoll Rand Nirvana Variable Speed Rotary Screw Air Compressors

Brand: Ingersoll Rand Nirvana Series - Product: Ingersoll Rand Centac Centrifugal Air Compressors

Brand: Ingersoll Rand Centac Series - Product: Ingersoll Rand R-Series Rotary Screw Air Compressors

Brand: Ingersoll Rand R-Series

Sullair:

- Product: Sullair LS Series Rotary Screw Air Compressors

Brand: Sullair LS Series - Product: Sullair ES Series Encapsulated Rotary Screw Air Compressors

Brand: Sullair ES Series - Product: Sullair DSP Series Oil-Free Rotary Screw Air Compressors

Brand: Sullair DSP Series

Bosch Rexroth:

- Product: Bosch Rexroth A10VO Axial Piston Variable Pump

Brand: Bosch Rexroth A10VO Series - Product: Bosch Rexroth A4VG Axial Piston Variable Pump

Brand: Bosch Rexroth A4VG Series - Product: Bosch Rexroth PV7 Axial Piston Variable Pump

Brand: Bosch Rexroth PV7 Series

Parker Hannifin:

- Product: Parker Hannifin P1/PD Series Hydraulic Pumps

Brand: Parker Hannifin P1/PD Series - Product: Parker Hannifin PVplus Variable Displacement Piston Pumps

Brand: Parker Hannifin PVplus Series - Product: Parker Hannifin F12 Fixed Displacement Piston Pumps

Brand: Parker Hannifin F12 Series

Eaton:

- Product: Eaton Vickers PVH Series Hydraulic Pumps

Brand: Eaton Vickers PVH Series - Product: Eaton Char-Lynn H Series Hydraulic Motors

Brand: Eaton Char-Lynn H Series - Product: Eaton Vickers PVM Variable Displacement Piston Pumps

Brand: Eaton Vickers PVM Series

INDUSTRIAL ROBOTS AND AUTOMATION EQUIPMENT

Robotic arms:

Robotic arms are versatile mechanical devices designed to mimic the function of a human arm. In the oil and gas industry, robotic arms are utilized for tasks such as welding, material handling, and inspection in hazardous or hard-to-reach environments. These arms can be equipped with various end-effectors and sensors to perform specific tasks accurately and efficiently.

Automated assembly lines:

Automated assembly lines consist of a series of interconnected robotic and mechanical systems that work together to assemble components or products. In the oil and gas sector, automated assembly lines can be used for constructing equipment such as valves, pumps, and drilling rigs. By automating the assembly process, companies can improve precision, reduce labor costs, and enhance throughput.

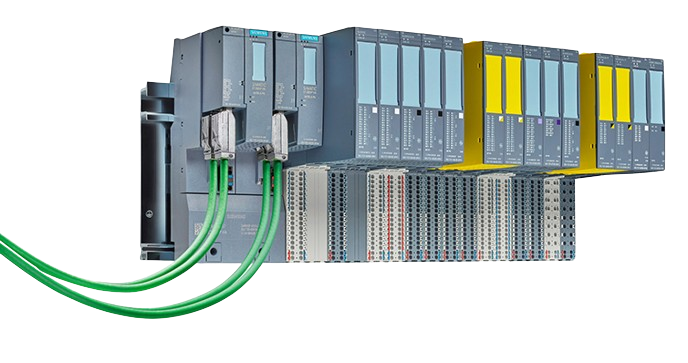

PLC (Programmable Logic Controller) systems:

PLC systems are specialized computers used to control industrial processes and machinery. In the oil and gas industry, PLCs are employed to monitor and regulate operations such as drilling, refining, and pipeline transportation. These systems can automate complex sequences of actions, ensuring optimal performance while maintaining safety standards.

Industrial robots (SCARA, articulated, delta robots):

Industrial robots come in various types, including SCARA (Selective Compliance Articulated Robot Arm), articulated, and delta robots. These robots are extensively used in the oil and gas sector for tasks such as material handling, welding, painting, and inspection. SCARA robots are often employed for precise assembly tasks, articulated robots for versatile applications in larger workspaces, and delta robots for high-speed, repetitive tasks.

Vision inspection systems:

Vision inspection systems utilize cameras and image processing algorithms to inspect and analyze components or products visually. In the oil and gas industry, these systems are employed for quality control, defect detection, and monitoring of equipment and infrastructure. Vision inspection systems can identify anomalies such as cracks, corrosion, or leaks, helping to prevent costly downtime and safety hazards.

INDUSTRIAL ROBOTS AND AUTOMATION EQUIPMENT

PRODUCTS AND MANUFACTURERS

Jump To:

Robotic arms:

- ABB Robotics

- Fanuc Corporation

- KUKA Robotics

Automated assembly lines:

- Siemens AG

- Rockwell Automation, Inc.

- Bosch Rexroth AG

PLC (Programmable Logic Controller) systems:

- Siemens AG

- Rockwell Automation, Inc.

- Schneider Electric SE

Industrial robots (SCARA, articulated, delta robots):

- ABB Robotics

- Fanuc Corporation

- KUKA Robotics

Vision inspection systems:

- Cognex Corporation

- Keyence Corporation

- Omron Corporation

ABB Robotics:

- Product: IRB 8700 Industrial Robot

- Product: FlexArc Welding Cell

- Product: IRB 8700 Inverted Mounted Robot

Fanuc Corporation:

- Product: FANUC M-2000iA/2300 Heavy Duty Robot

- Product: FANUC R-2000iC/210F Industrial Robot

- Product: FANUC LR Mate 200iD/4S Robot

KUKA Robotics:

- Product: KR 1000 Titan Heavy Duty Robot

- Product: KUKA KR QUANTEC Ultra Robot

- Product: KUKA KR AGILUS Series Robot

Siemens AG:

- Product: SIMATIC S7-1500 PLC

- Product: SIMATIC ET 200SP Distributed I/O System

- Product: SIMATIC WinCC SCADA System

Rockwell Automation, Inc.:

- Product: Allen-Bradley CompactLogix PLC

- Product: Allen-Bradley ControlLogix PLC

- Product: Allen-Bradley PanelView HMI

Schneider Electric SE:

- Product: Modicon M340 PLC

- Product: Modicon M580 ePAC PLC

- Product: EcoStruxure Machine SCADA Expert

Cognex Corporation:

- Product: In-Sight 7000 Series Vision System

- Product: In-Sight 8000 Series Vision System

- Product: In-Sight D900 Vision System

Keyence Corporation:

- Product: CV-X Series Vision System

- Product: IV Series Vision Sensor

- Product: XG-X Series Smart Camera

Omron Corporation:

- Product: Sysmac NJ Series Machine Automation Controller

- Product: Sysmac NX Series I/O System

- Product: FH Series Vision System