- +971 543 497 827

- enquiries@rigrock.ae

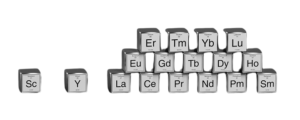

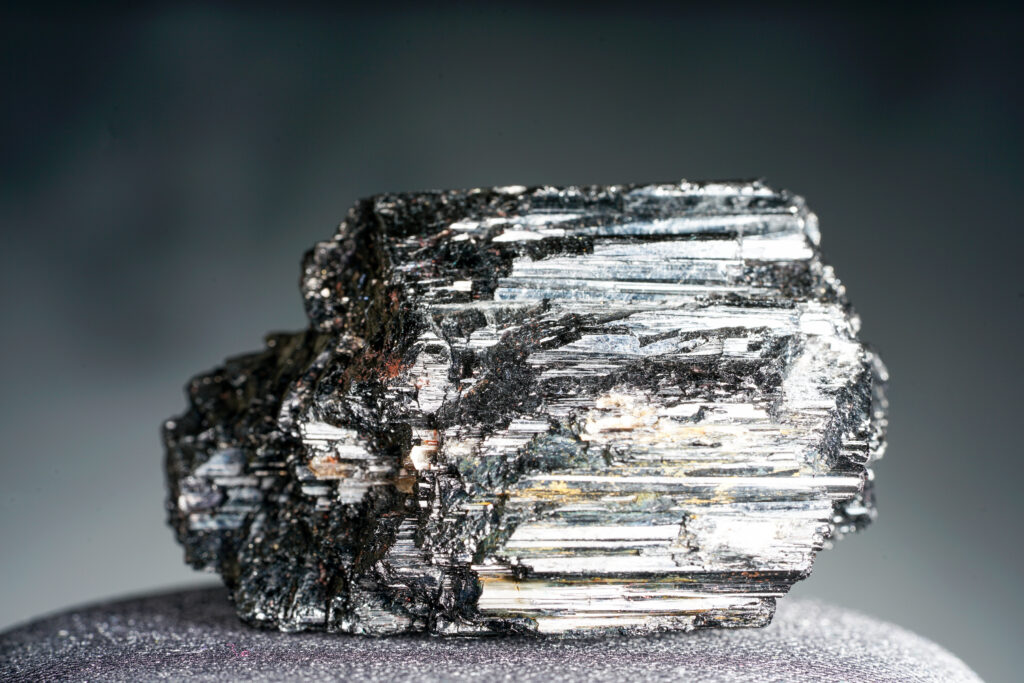

RARE EARTH METALS

Rare earth metals play a crucial role in the steel foundry industry by enhancing the properties of steel and ensuring superior performance in various applications. These elements, including cerium, lanthanum, and neodymium, are added in small quantities to improve the strength, ductility, and oxidation resistance of steel. Cerium and lanthanum, for instance, act as powerful deoxidizers and help in refining the grain structure, leading to higher quality steel. Neodymium and dysprosium are integral to the production of high-strength and magnetic steels, making them essential for specialized industrial applications. Yttrium is used to increase the high-temperature stability and oxidation resistance of steel, essential for components exposed to extreme environments. By incorporating these rare earth elements, steel foundries can produce materials that meet stringent performance standards, ensuring reliability and longevity in their products. Partnering with a reliable supplier of rare earth-enhanced steel ensures access to advanced materials that can drive innovation and efficiency in the foundry industry.

Cerium (Ce):

- Used to improve oxidation resistance and as a deoxidizer.

Lanthanum (La):

- Enhances the strength and workability of steel.

Neodymium (Nd):

- Used in high-strength steels and can improve the magnetic properties

of steel.

Yttrium (Y):

- Improves the high-temperature strength and oxidation resistance of steel.

Dysprosium (Dy):

- Used in high-performance magnets within steel alloys, enhancing

magnetic properties.

Praseodymium (Pr):

- Can be used to enhance strength and ductility.

Samarium (Sm):

- Utilized in specialized magnetic alloys and high-temperature materials.

Gadolinium (Gd):

- Used in certain high-temperature and magnetic applications.

These rare earth elements are typically added in small amounts to steel to achieve the desired improvements in properties such as strength, ductility, and resistance to oxidation and high temperatures.